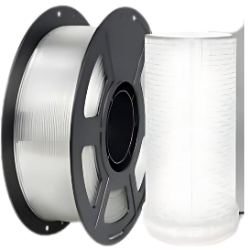

Bambu PETG-CF Carbon Fiber Filament 1.75mm

Inhouse product

-

৳12,300.00

৳13,500.00

Reviews & Ratings

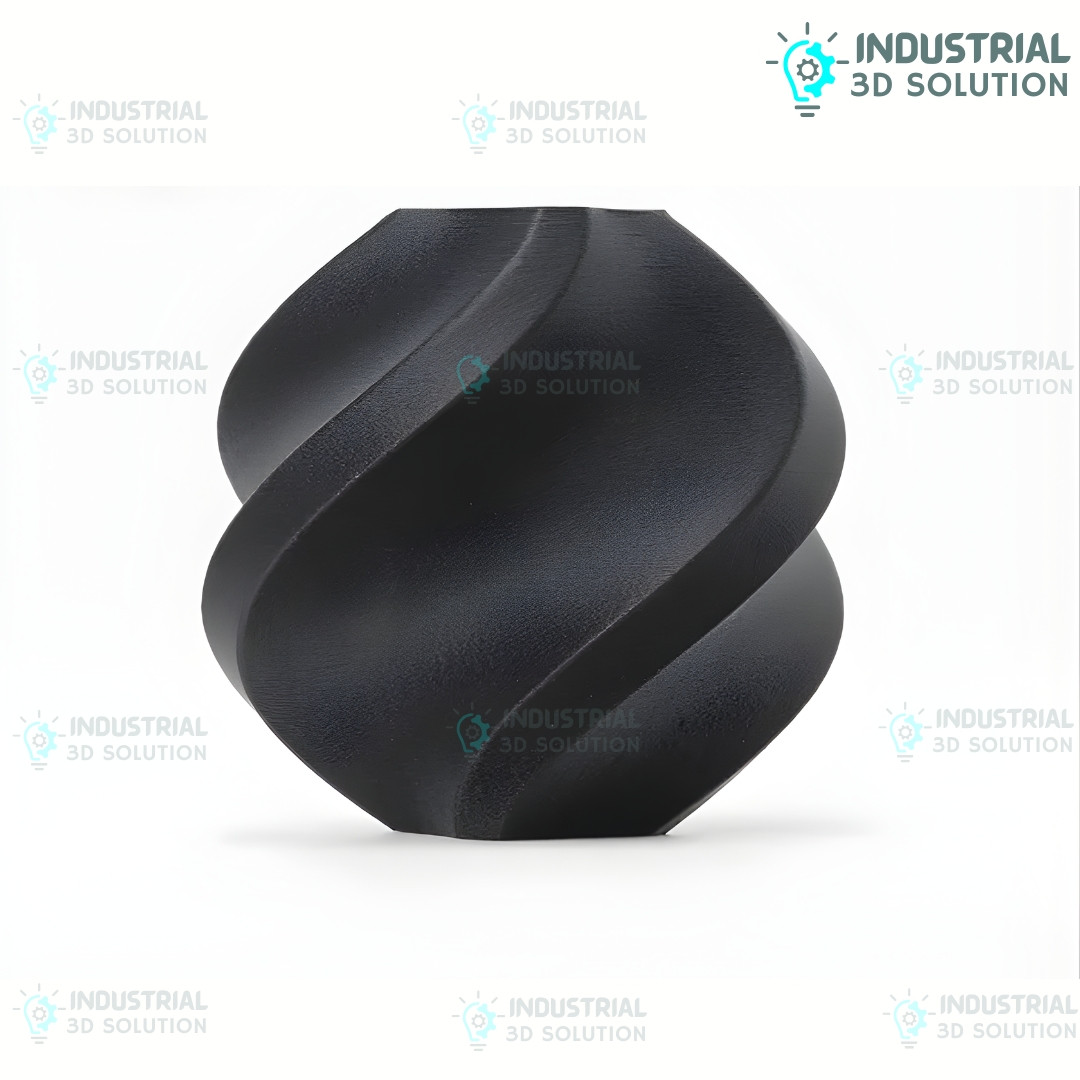

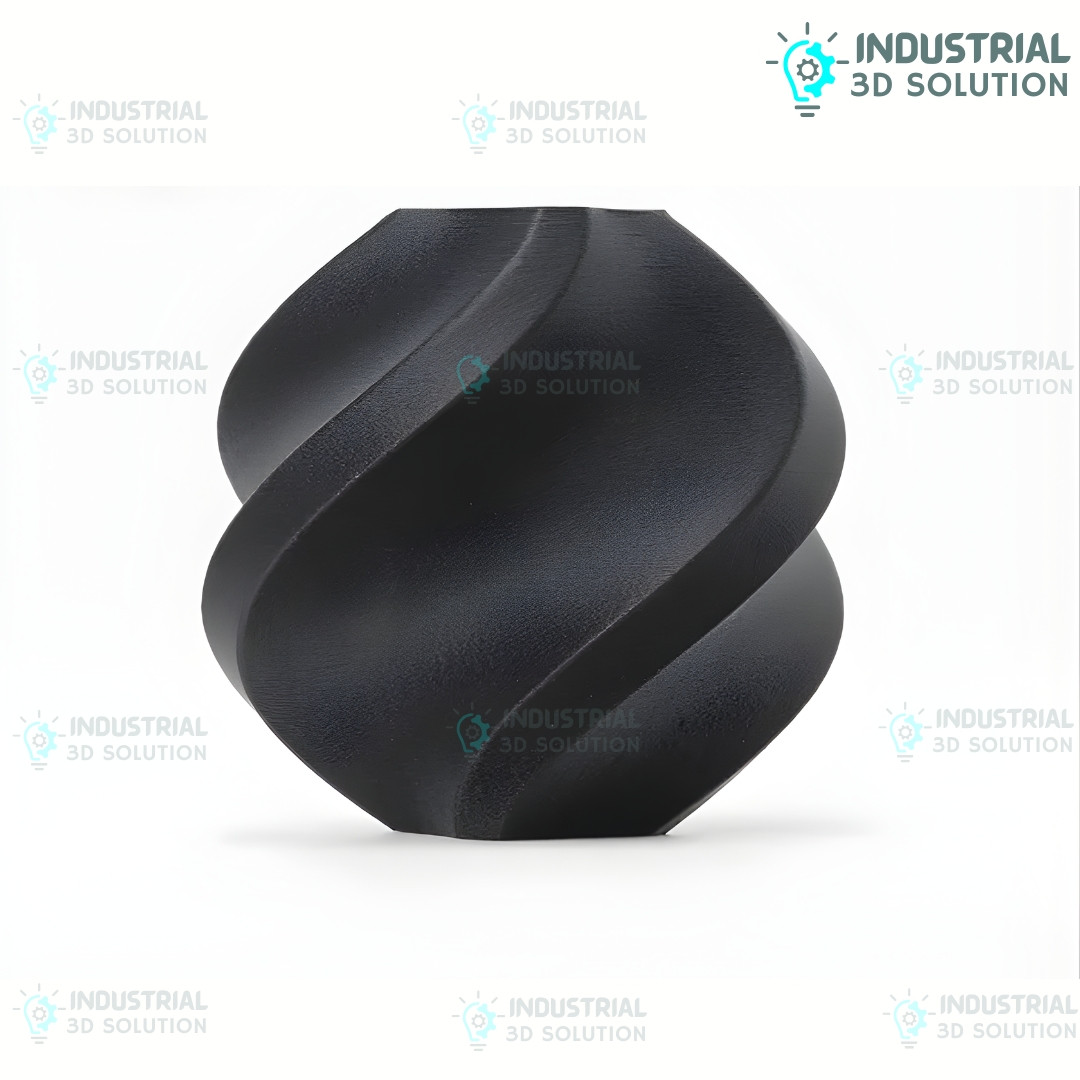

Bambu PETG-CF is a carbon-fiber-reinforced PETG filament engineered to significantly improve the stiffness, strength, and toughness of standard PETG. Designed as an all-rounder among engineering filaments, it is ideal for load-bearing, functional, and mechanical parts that require durability and dimensional stability.

The advanced formulation dramatically reduces clumping and stringing compared to regular PETG, ensuring cleaner prints and more consistent results. It delivers a distinctive carbon fiber texture with a glossier surface finish than PLA-CF, making it suitable for both functional and professional-looking parts.

Key Features & Benefits

Enhanced Strength & Stiffness

Cleaner & More Reliable Printing

Professional-Grade Compatibility

Improved Mechanical Balance

Cautions for Use

Drying & Storage Requirements

Recommended Printing Tips

Technical Specifications

| Material Type | PETG-CF (Carbon Fiber Reinforced PETG) |

| Filament Diameter | 1.75mm ± 0.03mm |

| Spool Type | Basic Reusable Spool |

| Surface Finish | Carbon Fiber Texture (Glossy) |

| Mechanical Properties | High Strength, High Stiffness, Tough |

| Flexibility | Improved compared to PLA-CF |

| AMS Compatibility | AMS 2 Pro, AMS HT, AMS |

| AMS Lite | Not Compatible |

| Nozzle Requirement | Hardened Steel (0.6mm Recommended) |

| Application | Load-bearing & functional parts |

Why Choose Bambu PETG-CF

-

Carbon fiber reinforcement overcomes the low stiffness of standard PETG

-

Improved strength and toughness for structural applications

-

Suitable for mechanical, load-bearing, and functional components

-

Significantly reduced clumping and stringing

-

Consistent extrusion with 1.75mm ± 0.03mm diameter accuracy

-

Premium carbon fiber surface finish

-

Compatible with AMS 2 Pro, AMS HT, and AMS systems

-

AMS Lite not compatible

-

Supplied on a basic reusable spool

-

Combines rigidity with high flexibility

-

Ideal for jigs, fixtures, brackets, enclosures, and engineering prototypes

-

0.2mm nozzle not compatible

-

Stainless steel nozzle not recommended

-

Use hardened steel nozzle only

-

0.6mm hardened steel nozzle recommended

-

0.4mm hardened steel nozzle usable with higher clogging risk

-

Proper drying is mandatory before printing:

-

Blast Drying Oven: 65 °C for 8 hours

-

AMS 2 Pro / AMS HT: 65 °C for 8 hours

-

X1 Printer Heatbed: 75–85 °C for 12 hours

After printing, store the filament in a sealed, dry container with desiccant.

-

Increase infill density for improved Z-axis strength

-

Avoid open-frame printers

-

Do not use excessive cooling fan speed

-

For a shinier surface finish:

-

Use lower printing speeds

-

Slightly increase nozzle temperature

-

-

Higher stiffness and strength than standard PETG

-

Cleaner prints with reduced stringing

-

Durable carbon fiber texture with professional appearance

-

Reliable for engineering and industrial 3D printing applications

Frequently Bought Products

Creality Copper Alloy + Hardened Steel 8PCS Extruder K1 Nozzle Kit Upgrade Kit

ELEGOO Neptune 4 Plus FDM 3D Printer

Creality Ender-3 V3

Creality Ender-3 V3 KE

Neptune 4 Max 3D printer

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00