Endmill Cutter (Multiple Sizes) – High-Precision Carbide Milling Tools for CNC Machines, Metal Cutting & Industrial Machining

Inhouse product

Request for Quote

-

৳12,300.00

৳13,500.00 -

৳680.00

৳750.00

Reviews & Ratings

Endmill Cutter (Multiple Sizes) – High-Precision Carbide Milling Tools for CNC Machines, Metal Cutting & Industrial Machining

Product Overview

This Endmill Cutter series delivers outstanding performance across machining tasks thanks to its solid carbide construction, multiple size options, and optimised flute geometry. Designed for professionals and facilities using CNC machines, metal fabrication, mould-making, and heavy-duty industrial machining, these cutters excel in materials such as stainless steel, carbon steel, aluminum, and more. With the ability to handle slotting, profiling, pocketing and finishing operations, these tools reduce cycle time, increase tool life and produce high quality finishes.

Whether you're machining delicate aluminum parts or robust steel components, this endmill cutter set (available in multiple diameters and lengths) allows you to match the right tool to the task — achieving high precision, efficient material removal and consistent surface finish.

Key Features

-

Multiple Size Options – a full range of diameters and lengths let you tailor the tool to your specific application and machine setup.

-

Solid Carbide Material – ensures high strength, excellent wear resistance, and longer tool life even under demanding conditions.

-

Precision Flute Geometry – optimised design for effective chip evacuation, reduced vibration, and smoother finish on metal surfaces.

-

Wide Material Compatibility – suitable for stainless steel, mild/carbon steel, aluminium, and other machinable materials.

-

Versatile Machining Capabilities – ideal for roughing, finishing, pocketing, slotting and contour machining tasks.

-

High Surface Finish & Accuracy – manufactured to tight tolerances, producing excellent finishes with minimal secondary finishing.

-

Tool-Friendly Design – compatible with standard shank holders and CNC tooling systems to streamline tool changes and inventory.

-

Durable Coating Options (if applicable) – optional TiN/TiAlN coatings for even greater performance and tool life in aggressive materials.

-

Professional Quality & Reliability – built for stable performance in industrial environments, reducing downtime and maintenance costs.

Technical Specifications

| Specification | Detail / Typical Value* |

|---|---|

| Tool Type | Endmill Cutter (Solid Carbide) |

| Material | Solid Carbide Body (optional coated variants) |

| Diameter Options | [List examples] e.g. 4 mm, 6 mm, 8 mm, 10 mm, 12 mm |

| Lengths Available | [List examples] e.g. 50 mm, 75 mm, 100 mm |

| Flute Count | 2-Flute, 4-Flute, etc (model dependent) |

| Shank Compatibility | Standard shank sizes (metric / imperial) |

| Coating (optional) | TiN, TiAlN or uncoated |

| Compatible Materials | Stainless Steel, Carbon Steel, Aluminium, Non-ferrous Alloys |

| Application Types | Slotting, Profiling, Pocketing, Finishing |

| Tolerance | High precision – tight manufacturing tolerances |

| Operating Conditions | Designed for CNC machining, industrial throughput |

| Tool Life & Durability | Enhanced via carbide & geometry |

| *Actual values depend on specific size/variant | See size chart for details |

*Actual specifications will vary based on the selected diameter, length and flute/geometry variant. Ensure selection matches your machine and material requirements.

Applications & Use Cases

-

CNC Machining Plants – for high-volume production of machined components in steel or aluminium.

-

Metal Cutting & Fabrication Workshops – ideal for mold making, mechanical parts and precision components.

-

Industrial Machining Lines – tools tailored to diverse operations: cutting, finishing, contouring.

-

Prototype to Production Transition – one tool-series covering both rapid prototyping and long-run jobs.

-

Multi-Material Machining – from tough stainless to soft aluminium, pick the correct endmill size/variant.

Benefits & Competitive Advantages

-

Reduced Tool Inventory Complexity – multiple sizes in one product line means fewer tool types to manage.

-

Improved Productivity – high precision and efficient geometry reduce machine cycle times and post-processing.

-

Cost-Efficiency – longer tool life and less downtime mean lower cost per part.

-

Superior Finish Quality – high precision manufacturing leads to better surface finish and less rework.

-

Flexibility Across Materials & Operations – one tool series for multiple materials and machining tasks.

-

Industrial-Grade Reliability – robust construction means less tool failure and consistent performance.

Frequently Bought Products

Hantek DSO2C10 100Mhz 2-Channel Oscilloscope Digital Storage 1GS/s

15V 1A DC Power Supply With Digital Display

Hydraulic pedal pump

TOLSEN Diagonal Cutting Pliers 7" Industrial Series

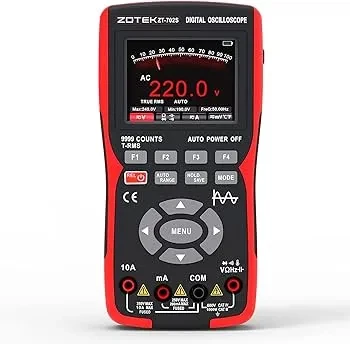

OYI ZT-702S 2IN1 10MHz Digital Oscilloscope Bandwidth 48MSa/s Multimeter

Product Queries (0)

Login Or Registerto submit your questions to seller

Other Questions

No none asked to seller yet

-

৳12,300.00

৳13,500.00 -

৳680.00

৳750.00